Cleanroom Monitoring

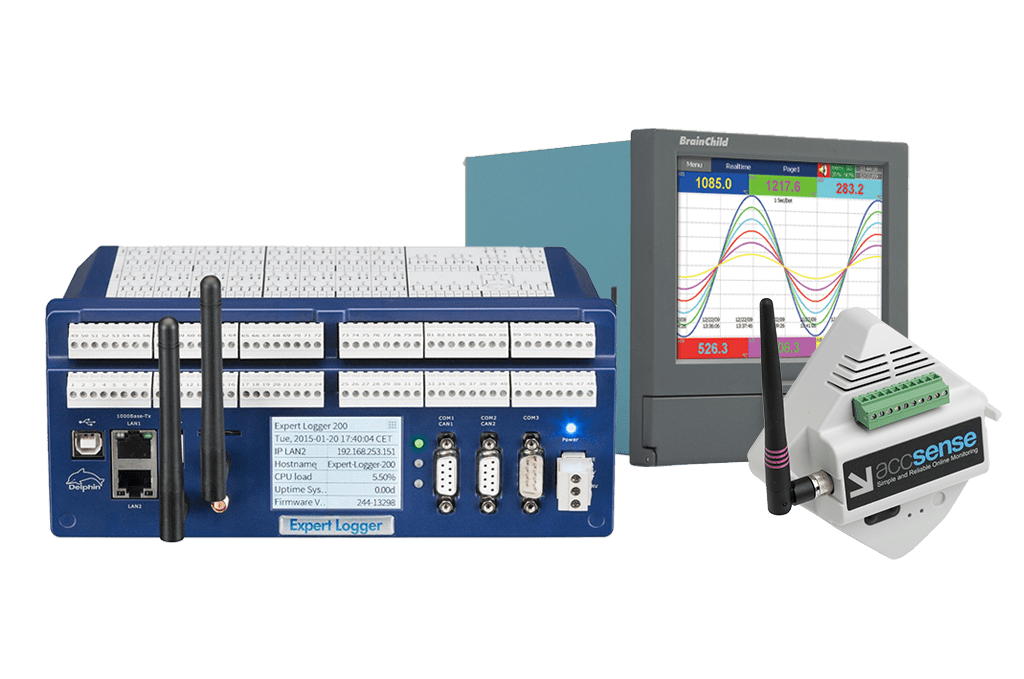

Cleanroom environmental monitoring systems to assure and certify sterility in cleanrooms, laboratories and other isolated areas that require users to monitor, record, alarm and validate data. Stand-alone and graphic display models are both available to help you prove best practices in your environment.

Avoid Contamination

Define your points, sample frequency and document results all with automated monitoring.

Learn More

Prove Best Practices

Trend data over time and analyze historical data for risk management and best practices.

Learn More

Keep Data Secure

Log and archive measurement parameters in a format safe from manipulation.

Learn More

Ensure Compliance

Handle constant healthcare monitoring while staying compliant with industry standards.

Learn MoreNeed to Speak to a Data Logging Specialist?

Fast & Easy Configuration

Cleanroom data recording is user friendly and intuitive configuration means fast installation and short training times will save you money.

Intelligent Signal Processing

Signal processing using internal software channels significantly simplifies measurement tasks and flexible calculation channels.

Actionable Alarms

Warning alerts are available to set recipients in case of an unwanted temperature change, keeping your assets protected.

Out Of The Box Setup

Start monitoring in your cleanroom application in minutes with a quick and easy setup with virtually no learning curve.

Data loggers used to monitor temperature, humidity, delta-pressure and even particle count. Provide historical data for QC and audits and generate alerts when parameters are out of spec to avoid contamination, improve quality and satisfy regulatory requirements.

View All Cleanroom Monitoring Solutions