How to Best Protect Your Vaccines and Temperature-Sensitive Products

Maintaining accurate temperature monitoring and alarm generation in medical refrigerators and freezers is crucial for ensuring product safety, particularly in the context of vaccine storage, blood and tissue preservation, and other pharmaceutical applications. While the Centers for Disease Control (CDC) provides general guidelines for temperature monitoring, there are several areas that lack specific recommendations such as the type of temperature buffers to use with probes. To address this gap, CAS DataLoggers conducted a comprehensive study to evaluate the various parts of the monitoring system including elements such as the effectiveness of different types of thermal buffers. The findings revealed that using a temperature buffer, such as a glycol bottle or nylon block, significantly improves the accuracy of temperature readings and reduces nuisance alarms caused by door openings and compressor cycling.

Here are seven key recommendations for effective temperature monitoring in medical refrigerators and freezers:

- Utilize temperature data loggers: Data loggers provide an accurate record of temperature history, allowing for better monitoring and analysis of product temperatures. They can also be configured to send real-time alerts in case of temperature excursions.

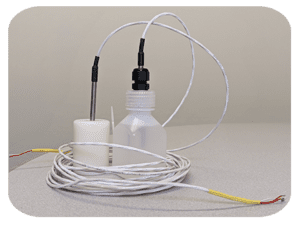

- Use temperature buffers on all probes: Temperature buffers slow the probe’s response rate, making it more closely reflect the actual temperature of the stored product. Glycol bottles are particularly effective in both refrigerators. Select a buffer type appropriate for the usage temperature – glycol bottles for temperatures above approximately -10°C, and nylon blocks for temperatures below this point.

- Position probes correctly: Place probes away from the evaporator coil or airstream of the coil fan to avoid fluctuations caused by compressor cycling. Avoid using dormitory or bar-style combination fridge/freezer units for medical storage as they tend to exhibit larger temperature swings than industrial/commercial units.

- Fill combination refrigerator/freezer units with water bottles: This helps regulate temperature and prevent freezing or excessive cooling of products.

- Monitor compressor cycling: Data loggers can display temperature graphs to visualize compressor cycling patterns. This information can be used to identify and control temperature fluctuations.

- Calibrate probes to NIST traceable standards when necessary: NIST calibration ensures the accuracy of probe readings and is often required for regulatory compliance and high-precision applications.

- Consider using CAS DataLoggers’ Accsense medical monitoring systems: Accsense systems are widely used by healthcare institutions and have earned the Joint Commission’s Gold Seal of Approval.

By adhering to these best practices, healthcare facilities can safeguard their valuable inventory, maintain regulatory compliance, and ensure the integrity of their medical products.

By adhering to these best practices, healthcare facilities can safeguard their valuable inventory, maintain regulatory compliance, and ensure the integrity of their medical products.

For more information on Accsense Medical Monitoring Systems, or to find the ideal solution for your application-specific needs, contact a CAS DataLogger Application Specialist at (800) 956-4437 or request more information.