Custom System Monitors Priceless Embryo Incubators

A prominent in-vitro fertilization clinic, that used our Accsense system for cryostat monitoring, was searching for a system to monitor their embryo incubators. The system had to provide continuous embryo incubator monitoring of temperature, humidity, CO2 level, and door openings. Each embryo incubator had a controller that was fitted with an analog output card to provide separate 4-20 mA current signals for temperature, humidity, and CO2 level. Door openings were to be captured via a standard magnetic reed switch similar to those used on burglar alarms. A key requirement was to monitor how long the door is open. They wanted the data updated every 10 seconds and uploaded via Ethernet to a custom embryo incubator monitoring system they had designed. Finally, the incubators were arranged in stacks of 3, so they were looking for a system that could measure a total of 9, 4-20 mA inputs plus 3 digital inputs for each stack.

A prominent in-vitro fertilization clinic, that used our Accsense system for cryostat monitoring, was searching for a system to monitor their embryo incubators. The system had to provide continuous embryo incubator monitoring of temperature, humidity, CO2 level, and door openings. Each embryo incubator had a controller that was fitted with an analog output card to provide separate 4-20 mA current signals for temperature, humidity, and CO2 level. Door openings were to be captured via a standard magnetic reed switch similar to those used on burglar alarms. A key requirement was to monitor how long the door is open. They wanted the data updated every 10 seconds and uploaded via Ethernet to a custom embryo incubator monitoring system they had designed. Finally, the incubators were arranged in stacks of 3, so they were looking for a system that could measure a total of 9, 4-20 mA inputs plus 3 digital inputs for each stack.

Monitoring System Design

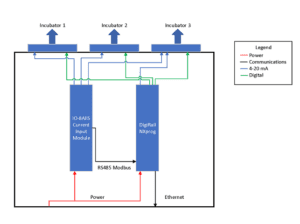

After doing a bit of searching, it was determined that there was not a simple off-the-shelf solution that satisfied all of the requirements at a price point that met the customer’s expectations for embryo incubator monitoring. In particular, the requirement to track not just door open events, but to also record the total time the door was open, proved to be challenging. Ultimately, we ended up designing a custom system using several standard I/O modules and a bit of custom programming. Figure 1 is shown below.

Figure 1. Block Diagram of the System

The main components are:

- A Brainchild IO-8AIIS Modbus I/O module with 8, 4-20 mA inputs. This module offered a standard RS-485 Modbus RTU interface for communication. This particular model also offered isolated current inputs to minimize the potential for interference between the different signals coming from 3 separate embryo incubators.

- A Novus NXprog RAMIX programmable I/O module with 2 universal analog inputs for voltage or current plus 4 digital inputs for the door switches. A key feature of digital inputs is the ability to configure them to act as integrators to accumulate time in a particular state.

- A custom Arduino program for the NXprog, which:

a. Reads the 8, 4-20mA current inputs of the Brainchild I/O module every 10 seconds plus one 4-20mA input connected directly to the NXprog.

b. Reads the 4 digital input time integrators of the NXprog every 10 seconds

c. Scales both of these sets of measured data to the appropriate units

d. Stores the scaled data in externally accessible registers for access via Modbus TCP using the built-in Ethernet port of the NXprog - A custom enclosure with external power and Ethernet connectors and magnetic feet to attach to incubator housing.

Figure 2. Finished System Box

Programming of the controller in the NXprog was greatly simplified by the use of the standard Arduino IDE and a comprehensive Arduino library with support of the various onboard I/O such as analog and digital inputs and outputs, RS-485 interface, and Modbus functions. All of the programming was done in the standard high-level Arduino language which was a framework built onto C/C++, so there was no special language to learn, unlike many other controllers or PLCs.

Benefits

This custom system provided a cost-effective way to simultaneously monitor all 3 incubators in the stack and provide the required data (temperature, humidity, CO2 level, and door open times). Measured data can be easily read by the customers monitoring application via Ethernet using the industry-standard Modbus TCP protocol. By creating a custom application with the Novus NXprog using the standard Arduino IDE and programming language, the customer can easily make modifications in the future if their needs change. The system provides the key information that the customer required to optimize their process, maximize the viability of the embryos, and increase the chance of success.

For more information on our Brainchild modules or Novus modules, or to find the ideal solution for your application-specific needs, contact a CAS DataLogger Application Specialist at (800) 956-4437 or request more information.